OK, I now know my Sholes Visible well enough that I could tell you right away where all (er, almost all) of these parts belong.

But even more disassembly is required! In order to get the machine as clean as possible, there's no way to avoid taking the keyboard apart.

Each key lever needs to be pushed backwards and down, then forwards to disengage it.

Halfway there. Scary, isn't it?

Almost done.

This is what key levers look like when they're out of the typewriter. The L-shaped hooks on the right fit into holes in what I'll call the "pullers," which pull down and activate the typing mechanism. On the left, each lever has an adjustable screw that activates the escapement, and a spring that pulls the lever back into position when you type.

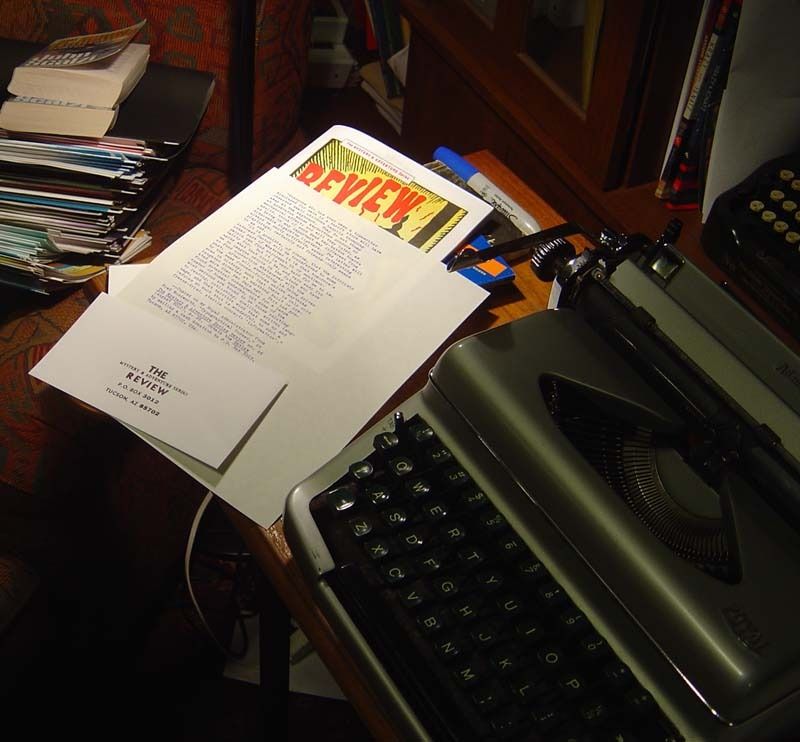

Yes, I'm taking notes!

Here's how the levers look a few hours later, after a bath in Evapo-Rust (which softens the rusty-looking grease and removes any actual rust), wiping dry, and touching up with steel wool.

The keyless typewriter:

The central mechanism can now be lifted out. NO, I'm not going to disassemble it!

Notice the little holes at the bottom of the vertical "pullers," where the L-shaped hooks on the type levers fit in.

Here's what the typewriter looks like now.

This weird set of contraptions can now be removed. From left to right you're looking at the ribbon vibrator, the guide for the "pullers," rectangular wires that activate the ribbon vibrator, and a mechanism that triggers the escapement.

Now, apart from a few pieces of hardware, we are down to the cast iron frame. Once I've cleaned it, it will await the return of all those pieces -- if I can remember where they go! (I told you, this stuff is scary.)